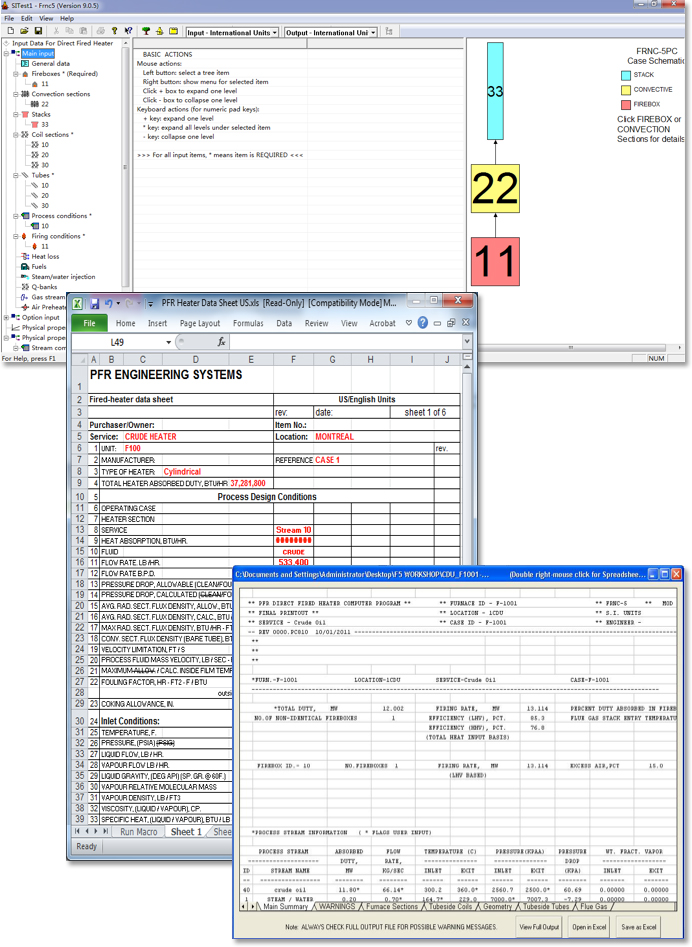

FRNC-5PC is a rating program for general purpose fired heaters. Based on user-supplied heater geometry, combustion data, and process information, the program calculates operating parameters such as firing rate, heater efficiency, tube skin temperatures and required tube thicknesses, gas-side temperatures and draft, process temperatures, pressure drop and flow regimes, heat duties and fluxes, and much more.

FRNC-5PC simulates entire radiant sections of most heater types, coil configurations, tube and fin types, ducting, stacks, and external transfer lines. FRNC-5PC can simulate the heat recovery sections of all types of furnaces, boilers and turbines.

FRNC-5PC has a user-friendly graphical input system and multiple, user-controlled output options, such as heater data sheets, graphical output, spreadsheet output and tabular output. The input system contains on-line help and input limit and error checking.

Reduce Heater Operating Costs

•Lower heater fuel consumption

•Evaluate air leakage, air preheaters and heat recovery coils

Increase Heater Capacity

•Identify thermal, hydraulic and draft limits

•Model process controls

•Minimize excess air for NOx control

Evaluate Process Changes

•Stream rates, temperatures and compositions

•Steam injection

•Process stream flow regimes and vaporization

•HAZOPS and Process Safety Management reviews

Check New Heater Designs

•Optimize capital expenditures

•Determine firebox and overall heater efficiencies

•Evaluate most boiler types

Minimize Unplanned Shutdowns

•Provide detailed tube skin temperature and tubewall thickness profiles

•Evaluate fouling and coking effects

•Train engineers to troubleshoot heaters

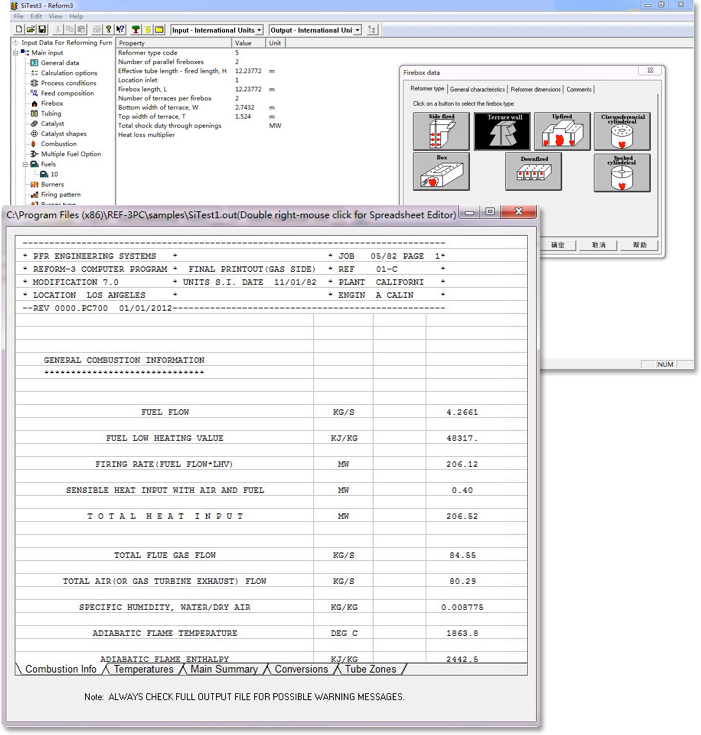

REFORM-3PC is a rating program for the firebox sections of Steam-Methane Reformer furnaces, which are used in Hydrogen, Ammonia and Oxo-Alcohol production. Based on user-supplied furnace geometry, combustion and catalyst data, and process information, the program calculates operating parameters such as firing rate, furnace efficiency, tube skin temperatures, gas-and process-side temperature profiles, heat duties, process composition profiles, and fluxes.

REFORM-3PC simulates most reforming furnace types such as Up, Down, or Side Fired rectangular and cylindrical types, as well as Terrace Wall. It can model any catalyst shape or size. REFORM-3PC performs process-side kinetics calculations based on stream composition and temperature for each tube increment. The program uses a 3-dimensional flue gas zone analysis and accurate process-side kinetics for each tube increment. Both primary and secondary (combustion) reactions are calculated.

REFORM-3PC has a user-friendly graphical input system and multiple, user-controlled output options, such as, graphical output, spreadsheet output and tabular output. The input system contains on-line help and input limit and error checking.

REFORM-3PC can model gas or liquid fuels and can be run in full performance rating mode or simple thermodynamic prediction mode to get overall reaction yields. The program calculates both circumferential and longitudinal tube wall temperature profiles.

Furnace Rating and Optimization

¡¡¡¡•Decrease Fuel Usage

¡¡¡¡•Extend Tube Life

¡¡¡¡•Evaluate Process Variable Changes

¡¡¡¡•Evaluate Fuel, Firing or Burner Changes

¡¡¡¡•Determine Efficiency and Heat Flux Profiles

¡¡¡¡•Monitor Catalyst Activity

¡¡¡¡•Evaluate Firebox or Tube Modifications

¡¡¡¡•Optimize Steam and Recycle Flows

¡¡¡¡•Use as HAZOP or Benchmarking Tool

Furnace Designs

¡¡¡¡•Perform, Check or Compare Designs

¡¡¡¡•Rate Alternate Operations

¡¡¡¡•Check Variations to Specs

¡¡¡¡•Check Burner Types and Locations

¡¡¡¡•Evaluate Proposed Catalysts

¡¡¡¡•Develop Process Control Algorithms

Copyright of ClearWaterBay (Beijing) Technology |